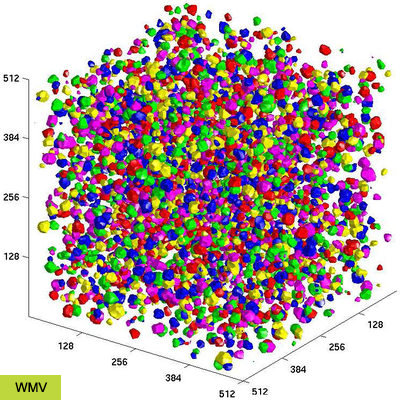

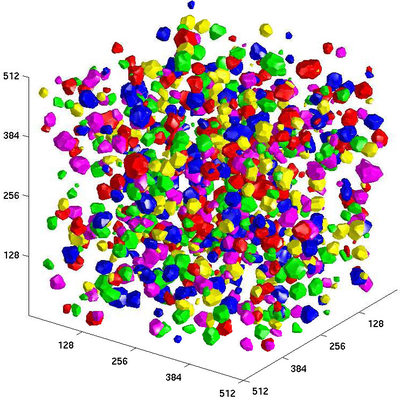

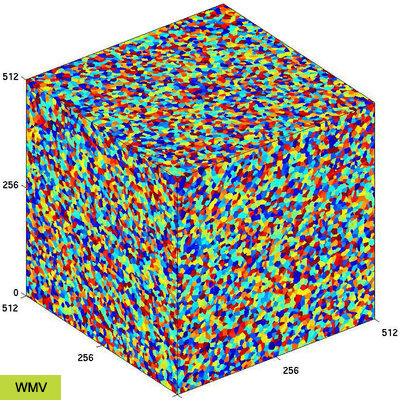

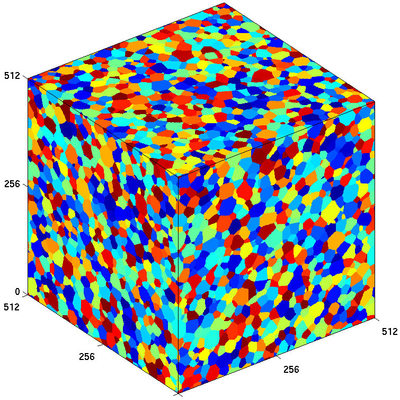

Many common materials, such as most metals and ceramics, are polycrystalline: They are made up of tiny crystallites called grains that are distinguished from their neighbors by their differing crystallographic orientation. When these materials are heated (i.e. annealed) -- for instance during a manufacturing process -- grain growth occurs: The network of grains decreases its energy through a coarsening procedure, which involves the growth of some of the grains at the expense of others. Statistical measures of the grain network, such as the grain size distribution, have important implications for the macroscopic properties of the material, such as its conductivity and brittleness. As such, simulating how the grain network evolves is of great technological interest. We developed new, efficient, and accurate numerical methods for simulating grain growth and related dynamics. This work has been supported by NSF grant DMS-0748333.

Publications and Preprints: